At EMMAY, we partner with our clients, understand their goals, providing leadership and organization to produce designs and workplans to achieve their requirements in terms of function, budget, constructability, safety, and sustainability.

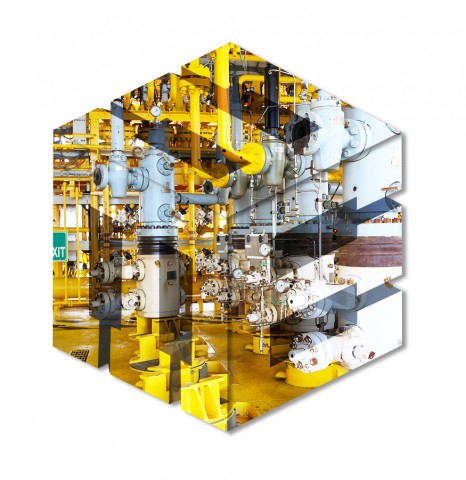

EMMAY’s engineering solutions encompass wide-ranging services, including concept selection/feasibility studies, FEED, basic and detailed engineering-only and EPC projects for capital instalments/de-bottlenecking, brown-fields, and revamps. The depth of our expertise is demonstrated across the core disciplines of process, civil, structural, mechanical (static and rotary), piping, electrical, instrumentation & control and package equipment. Our engineers are also supported by many specialist teams including design safety, architecture, environmental, pipelines and materials.

We provide the platform of specialized engineers and accompanying staff to handle complex and large scale plants keeping quality and schedule in-tact for procurement, construction and commissioning activities till the safe hand-over of the facility to our client’s operations teams. This requires creative thinking, innovation and analytical abilities on which we have developed our foundation over the past decades working closely with our customers and vendors/suppliers.

Engineering

Value Engineering